by Lucas Caldeira

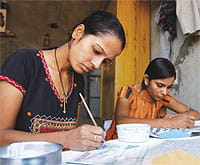

In India, most arts and craft businesses are carried out on a small scale in the homes of the artisans and producers. Usually, one room is used as a workshop. This room is often also used as a bedroom at the end of a hard day’s work. Asha Handicrafts is very aware of the challenges to reduce risks and ensure healthy and safe working conditions for all the artisans and producers they work with.

Minimum standards

Asha Handicrafts has set up minimum health and safety standards and all of the artisans and producers they work with are expected to follow them. The workshop has to be well lit and ventilated to ensure good working conditions. As the businesses develop, Asha Handicrafts invests the profits in improving the workshops:

-

Water filters are fitted in the workshops to provide safe drinking water. This is important as the majority of diseases are due to unsafe water.

-

The electrical wiring of the workshop is inspected and, if necessary, it is rewired to ensure that there are no accidents due to short circuits or faulty wiring.

-

Artisans and producers are made aware of the dangers of connecting loose wires directly into electric sockets, as this can cause a fire.

-

A fire extinguisher is placed in the work shop in case of a fire. It could also be used for putting out fires in the local area.

Environmental awareness

Asha Handicrafts’ Environment Advisor spends time with the artisans and producers to create awareness about the importance of using surgical masks during processes that generate dust. They are also educated about the importance of disposing of their production waste responsibly. Large bins have been provided to producers of wood products to help them collect the sawdust and wood shavings. These are then given to poor people to be used as firewood.

Preventing accidents

The belts of a lathe machine can cause accidents if they are at floor level. The artisan’s traditional flowing clothes can easily become caught in the machinery. This can cause serious accidents including the loss of a finger or limb. Producers are therefore advised to install the belts vertically. This is much safer and also releases the floor space which can be used for other activities.

Lucas Caldeira is the Head of Management at Asha Handicrafts, 28 Suren Road, Andheri East, Mumbai 400093, India. Email: [email protected] Web: www.ashahandicrafts.net

A case study

Improving life, livelihood and lifestyle

Stone and marble crafts have always posed a challenge to the health of the artisans who make them. Making stone products generates a lot of dust. The artisans are regularly covered in fine dust from head to toe. They also breathe in the dust particles that float around the workshop all the time.

This problem was noticed by the staff of Asha Handicrafts during their visit to the workshop of one of their producers, R.C. Marble Handicrafts. The first step was to find out how the production process could be improved to eliminate this health hazard.

Solving the problem

A consultant quoted a very high price to solve the problem, so Asha Handicrafts asked the lead artisan, Ramesh Chand Sharma, to suggest a solution. He suggested an underground passage fitted with a series of exhaust fans that would suck the dust out of the workshop as it is created. Asha Handicrafts consulted the manufacturers of exhaust fans for technical specifications and finalised the drawing. The plan was shown to a mechanical engineer who said that it would work, even though it was a low tech solution.

At the time Ramesh Chand, his brothers and their families lived together. Three rooms on the ground floor of their house were used as the workshop. It was not possible for the new dust extractor system to be installed in the house. A new workshop would be needed for the dust extractor system to work. Funding from Asha Handicrafts and Tearfund enabled the work to start. Seeing the concern and commitment of Asha Handicrafts and Tearfund for their health and safety, Ramesh Chand offered to raise the remaining amount required to complete the building.

A year later, a suitable plot of land was located and purchased. Initially, Ramesh Chand found it impossible to get a bank loan as the bank managers considered him a high credit risk. Asha Handicrafts supported him to get a loan from a bank. This was used to complete the project. The interest rates were also reduced to make it easier for him to repay the loan. After three years, the new production workshop with the innovative dust extractor system was opened.